- Skype/Email

- sale@luofuvalve.com

- Quick Contact:

- +86-21-6978 3899

PRESSURE SAFETY VALVE

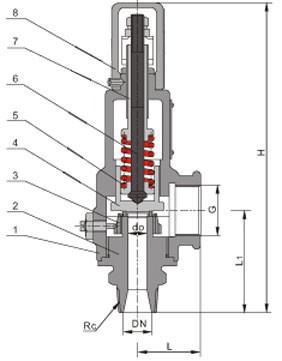

A22H/Y/W/F spring fully open closed safety valve

- Product Category:PRESSURE SAFETY VALVE

- Product Name:A22H/Y/W/F spring fully open closed safety valve

- Product Tag:Pressure Safety Valve Manufacturer In China

- Contact Us

Product Usage

A22 threaded connection spring full-open valve is a kind of non-hazardous and non-flammable and explosive gas or liquid medium pipeline and container as the final protection device for overpressure protection. This type of valve adopts spring direct load type, thread Connection, fully enclosed structure.

A22H/Y/W/F spring full-open closed safety valve is a safety protection valve for closed systems. Its opening and closing parts are normally closed under the action of external force. When the medium pressure of the closed system rises, it exceeds The safety valve is automatically opened when the value is specified, and the system pressure is reduced by discharging the medium to the outside of the system to prevent the destruction of the high-pressure system of the medium in the system. Safety valves belong to the category of automatic valves, which are mainly used in boilers, pressure vessels, air conditioners, and solar energy pipelines. The control pressure does not exceed the specified value, and it plays an important role in protecting personal safety and equipment operation.

Features

1. Full-open structure, large displacement 2. Threaded connection, convenient installation 3. Small size, economical and practical

Executive standard

A22 threaded connection spring full lift safety valve executive standard

| Design specification | GB/T 12243 |

| Structure length | GB/T 12221 |

| Flange connection | JB/T 79 |

| Test and inspection | GB/T 12242 |

| Product Identification | GB/T 12220 |

| Supply specification | JB/T 7928 |

Product number

A22H-10(16) A22H-16C(25,40) A22Y(H,W)-16P(25P,40P)

A22Y(H,W)-16R(25R,40R) A22Y(H,W)-16R3(25R3,40R3)

Selection conditions of safety valve

1. The nominal diameter of the selection valve of the nominal diameter should be determined according to the necessary discharge volume of the protected system. That is, the rated displacement of the selected valve should be greater than the necessary discharge. The discharge volume required by the protected system refers to the amount of medium that must be discharged to prevent excessive overpressure when abnormal overpressure occurs in the system. It is determined by factors such as the working conditions and capacity of the system or equipment, and the possible causes of overpressure. .

2. Material determination The material of the valve should consider various factors such as the working temperature and pressure of the medium, the characteristics of the medium and the manufacturability and economy of the material. Under normal circumstances, the user can choose according to the working temperature, pressure range and use medium of the different types of valves listed in the valve samples provided by the company. If there are special requirements for the material, it can be settled through negotiation with our company when ordering.

3. Selection of special structure valve

(1) Valve with radiator. This type of valve is generally used in occasions where the medium temperature is relatively high, so as to reduce the temperature of the spring chamber. Generally, when the operating temperature of the closed valve exceeds 300°C and the operating temperature of the open valve exceeds 350°C, a valve with a radiator structure should be selected. (2) Bellows valve (back pressure balanced valve) This valve should be selected when the valve is subjected to additional back pressure, and the back pressure change exceeds 10% of the set pressure. In addition, for valves used in corrosive and toxic media, bellows valves should also be selected in order to prevent the spring and guide mechanism from being corroded by the media. (3) Air-operated butterfly valve For high-temperature and high-pressure valves, when the opening pressure needs to be controlled manually, the cylinder function can be used for operation, and the air-operated butterfly valve should be selected.

Set pressure level

A22 threaded connection spring full-open valve setting pressure level

| Nominal pressure (MPa) | Set pressure level | |||||||

| 1.6 | 0.06~0.1 | 0.1~0.16 | 0.16~0.25 | 0.4~0.6 | 0.6~0.8 | 0.8~1.0 | 1.0~1.3 | 1.3~1.6 |

| 2.5 | 1.3~1.6 | 1.6~2.0 | 2.0~2.5 | |||||

| 4.0 | 1.3~1.6 | 1.6~2.0 | 2.0~2.5 | 2.5~3.2 | 3.2~4.0 | |||

Performance parameter

Performance parameters of A22 threaded spring full lift valve

| model | Cast iron type A22H-10/16 |

Cast steel type A22H/YC |

304 stainless steel type A22H/W/YP |

316 stainless steel type A22H/W/YR |

316L stainless steel type A22H/W/Y-R3 |

|

| Caliber range | DN15~DN80 | |||||

| proper temperature | ≤200°C | |||||

| Applicable medium | Water, steam, oil | Water, steam, oil | Corrosive medium | Corrosive medium | Corrosive medium | |

| Material | 1. Valve body | HT200 cast iron | WCB | CF8 | CF8M | CF3M |

| 2. Valve seat | 35#steel | 2Cr13 | CF8 | CF8M | CF3M | |

| 3. Adjustment ring | 2Cr13 | 2Cr13 | 304SS | 316SS | 316L | |

| 4. Valve clack | 2Cr13 | 2Cr13 | 304SS | 316SS | 316L | |

| 5. Spring | 50CrVa | 50CrVa | 50CrVa coated TEFLON | 50CrVa coated TEFLON | 50CrVa coated TEFLON | |

| 6. Valve stem | 2Cr13 | 2Cr13 | 2Cr13 | 316SS | 316L | |

| 7. Adjust the screw | 45 # steel | 45 # steel | 2Cr13 | 316SS | 316L | |

| 8. Protective cover | ZG200 | ZG200 | ZG200 | CF8M | CF8M | |

| Sealing surface material | Surfacing D507 alloy | Surfacing D507 alloy | Surfacing Co-based cemented carbide | Surfacing Co-based cemented carbide | Surfacing Co-based cemented carbide | |

Main external connection size

A22 threaded connection spring full lift valve main external connection dimensions (mm)

| Nominal diameter | Size(mm) | |||||

| DN(mm) | do | R | L | L1 | G | H |

| 15 | 10 | 1/2" | 37 | 62 | 3/4" | 189 |

| 20 | 12 | 3/4" | 40 | 65 | 1" | 196 |

| 25 | 15 | 1" | 45 | 72 | 1-1/4" | 277 |

| 32 | 20 | 1-1/4" | 50 | 85 | 1-1/2" | 312 |

| 40 | 25 | 1-1/2" | 55 | 100 | 2" | 322 |

| 50 | 32 | 2" | 67 | 112 | 2-1/2" | 348 |

| 65 | 40 | 2-1/2" | 76 | 135 | 3" | 370 |

| 80 | 50 | 3" | 110 | 145 | 4" | 410 |